Gemmological studies of “Hybrid Diamond” (Natural + CVD synthetics)

Introduction

Size and quality of CVD synthetic diamonds for jewelry market have been improved over the years, and various fancy colour CVD diamonds have also been produced. In addition, overgrowth of type IIb blue CVD synthetic diamond on colourless natural diamond has been made, aiming at fancy colouration (Moe et al., 2017, Ardon et al., 2019), and colourless natural diamond on which CVD diamond layer has been overgrown with the aim of increasing its weight has been reported (Serov et al., 2017., Tan et al., 2018). Appearance of these natural diamonds with CVD overgrowth layer, so called “hybrid diamonds” constitute a new challenge for diamond identification. For this report, we have overgrown a CVD diamond layer on a natural diamond substrate with a target thickness of 2000 μm, and performed gemmological observations after cutting and polishing in order to investigate possibilities of commercial benefits and gemmological detection of such “hybrid” diamonds.

Materials and Methods

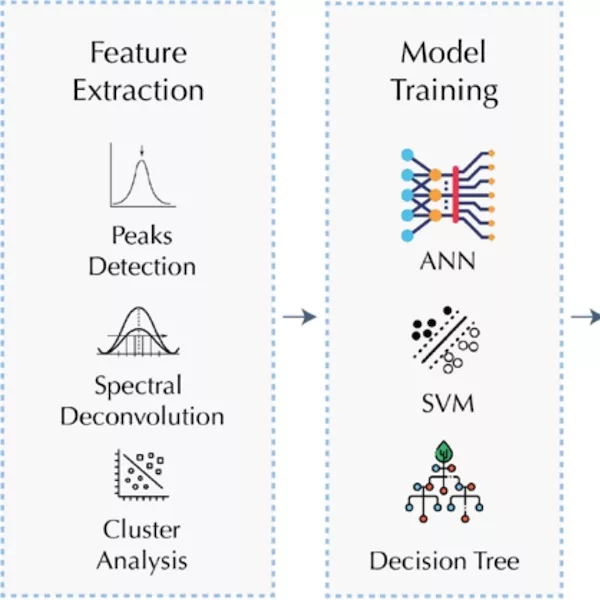

The CVD overgrowth and cutting/polishing process were performed at Diamond Elements Pvt. Ltd. India, and gemmological observations were performed at Central Gem Laboratory (CGL), Japan. Two apparently colourless octahedral type Ia natural rough diamonds (1.570ct and 1.049ct) were divided by center sawing to obtain four substrates. The CVD overgrowth was performed using a MP-CVD system (Seki Technotron Corp. , SDS6K) at temperatures of 1050- 1100 °C, a pressure of 150 Torr, and a growth rate of 12 μm/ hour. In order to grow the colourless layer so that the layer is not discerned from the natural diamond substrates, strict temperature control around the substrates was required. A special holder was designed to grow the diamond layer with the same quality on each of the four substrates in a single step. After growing the layer of a target thickness of 2000 μm, 3 of the 4 grown stones were cut and polished to square modified brilliant cut (Fig.1). These faceted stones were subjected to standard gemmological examinations: UV-Vis Absorption Spectroscopy, FTIR Spectroscopy, DiamondViewTM observation, Photoluminescence Spectroscopy and SYNTHdetect.

Results

Sample 1 was 0.494 ct, G colour, SI1 clarity, and the CVD layer thickness was 1100-1200 μm. Sample 2 was 0.391 ct, H colour, I2 clarity, and the CVD layer thickness was 660- 910 μm. The natural parts of Sample 1 and Sample 2 are cut from the same rough crystal. Sample 3 was 0.329 ct, H colour, I2 clarity, and the CVD layer thickness was 880- 940 μm.

Standard Gemmological Observation

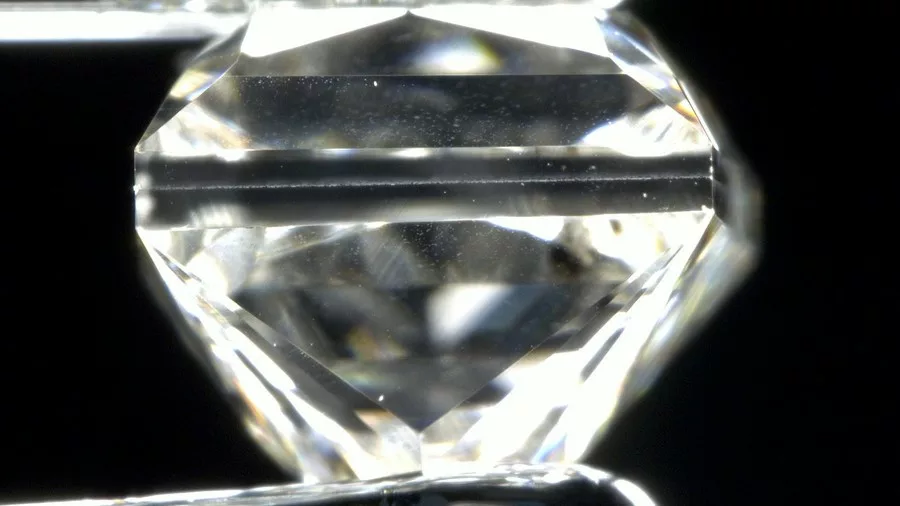

Observation using a gemmological microscope showed black inclusions in all three samples, and these were the main sources affecting clarity grade. It was confirmed that these black inclusions are located near the boundary between the CVD growth layer and the natural seed crystal used as the substrate. In addition, pinpoint-like inclusions were distributed at the boundary. Under cross-polarized light, strain birefringence parallel to the octahedral plane was observed in the natural seed crystal, and brush-like strain birefringence was observed in the CVD growth layer. In samples 1 and 2, a boundary between the seed crystal and the CVD growth layer was observed on the girdle (Fig.2).

Conclusions

CVD synthetic diamonds were overgrown on type Ia natural diamond. In order to grow CVD synthetic diamonds with the same colour as natural diamonds, growth temperature was precisely controlled around the natural diamonds used as substrates. In general, overgrowth on small stones would have little commercial benefit, but large crystals may give some profit. Since the diamonds contains type Ia natural diamonds, they may be misidentified as natural by rough sorting methods such as UV transparency, N3 defect detection, and bulk FTIR measurement. But SYNTHdetect judges as refer, when inspected from the table side (CVD part). The presence of black inclusions and minute inclusion distributed on the plane and characteristic strain birefringence are clues for detecting the CVD overgrowth. Concludingly, our study shows that it is possible to identify “hybrid diamonds” by combining data obtained from advanced identification techniques such as DiamondView and PL spectroscopy as well as standard methods.

References:

- Ardon T. and McElhenny G., 2019. Lab Notes: CVD layer grown on natural diamond. Gems & Gemology, 55(1), 97-99.

- Moe K.S., Johnson P., D’Gaenens-Johansson U. and Wang W., 2017. Lab Notes: A synthetic diamond overgrowth on a natural diamond. Gems & Gemology, 53(2), 237-239.

- Serov R., Shelementiev Y. and Serova A., 2017. Hybrid diamonds: Natural diamonds overgrowth with CVD synthetic. 35th International Gemmological Conference, Windhoek, Namibia 11-15 October, 51-53.

- Tan S., Su J., Lu T., Ma Yongwang., Ke J., Song Z., Zhang J. and Liu H., 2018. A thick overgrowth of CVD synthetic diamond on a natural diamond. The Journal of Gemmology, 36(2), 134-141.