Proposed New Filler Type for Emerald Fracture Filling: Design, Detection, Differentiation, Disclosure

Introduction

Fracture filling is common in gem trading to enhance gemstones’ beauty and / or durability. Common textbook examples are (lead) glass filling of rubies and diamonds, polymer/resin type filler impregnation of aquamarine, quartz, tourmaline, opal, turquoise, etc. Undoubtedly, the most common practice will be fracture filling of emeralds (Hänni, 1993) which involves the introduction of filler material to decrease the visibility of surface-reaching fractures so as to enhance the overall apparent clarity. In certain scenarios, the filler may also aid in increasing the stability of emeralds during the cutting process.

Common fillers used in the trade for emeralds can be classified into oils, resins, polymers/prepolymers, and wax (Johnson et al., 1999). These fillers are usually organic in nature. In this work certain new fillers are being proposed. The properties, method of introduction, detection and disclosure (qualitative and quantitative) will be discussed.

The RI matching, volatility and acceptability issue

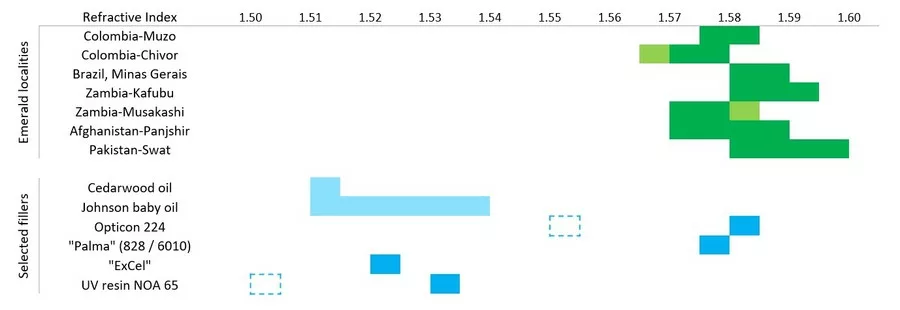

Traditionally the lower RI Colombian emeralds are better matched with oil-type fillers. However, with the introduction of higher RI emeralds like Pakistani emeralds, resin-type fillers will be a better alternative, (Figure 1). In terms of evaporative stability, resin-type fillers are much more stable than oils thus no “re-oiling” is required after months. However, for end users resins are synonyms for “artificial glues” and consider less acceptable. Therefore, there is a need for a search of “all-round” filler.

The ideal filler

For a filler suitable for commercial manipulation, it should possess the followings:

- RI compatibility: the closer the RI between the filler and the gemstones to be treated, the lesser the fractures visibility. For emeralds, this is origin dependent (Figure 2).

- Stability: fillers should be stable towards light, moisture, temperature and various chemicals. The colour should not change over time. (Bergman, web resource)

- Viscosity: preferably free-flowing during treatment for better penetration but become more viscous and stay inside the fissures.

Additional optional properties include:

- Occurrence: end users usually prefer natural over synthetic or artificial substances.

- Removability: some traders prefer emerald filler to be removed from stones for extra manipulation.

New filler type in this work

There are two new directions proposed in this work: 1. Liquid with tuneable RI (TRI) and 2. Inorganic filler (IF).

1. Liquid mixture comprising a “base oil” and a high RI liquid.

In this work different combinations of high RI liquid such as diiodomethane (RI 1.74), bromonaphthalenes (RI 1.64- 1.66) is mixed with “base oil” such as baby oil (RI 1.52), paraffin oil (RI 1.44-1.45), Glycerin (RI 1.47), ethylene glycol (RI 1.43). The base oil serves the purpose of: a. adjusting the RI suitable for the emerald of interest, b. provide viscosity, c. provide certain functional groups for subsequent sealing purposes (see below). In this work mixtures with RI range of 1.56-1.61 have been prepared for fitting different emeralds. (Figure 3).

2. Inorganic filler material

In this work sodium silicate solution (RI 1.51-1.52) was used as the first suitable candidate for its low toxicity and availability. Since water tension is an issue for fracture filling, a surfactant such as sodium dodecyl sulfate (SDS) was incorporated into the solution.

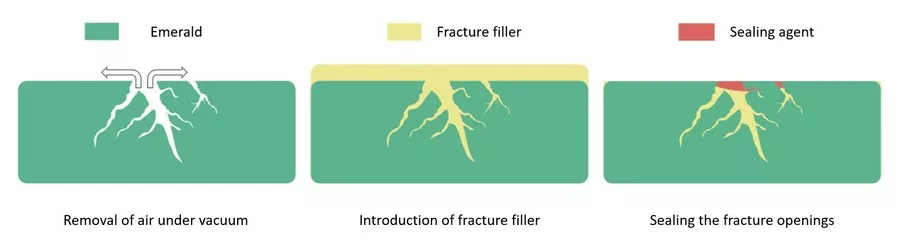

The fracture filling process with sealing

As both the aforesaid TRI and IF fillers are susceptible to evaporation, a sealing process is introduced to complete the filling process. In a routine approach, the emeralds follow the reported processes of acid cleaning followed by vacuum pumping. After the introduction of the filler material with or without pressure the filled emeralds are taken out from filler solution and subject to a sealing chemical reaction. For TRI liquid mixtures with ethylene glycol base oil, attempts have been made by esterification with organic acids (acetic acid, amino acid) of the surface filler to form a solid (Figure 4). For IF attempts have been made by using citric acid or oxalic to produce silica gel as a fracture opening sealer. With this process, the overall filler may be classified as a “composite” filler type.

Detection of treatment

Detection of TRI filler is straightforward and follows the protocol for normal oil-type fillers: aliphatic C-H stretching related FTIR peaks, colour flashes etc. (Kiefert et al., 1999) For IF, however, only the luster difference at fracture openings is observed with no classic “organic materials’ FTIR peaks nor fluorescence, Careful inspections are required for proper qualitative and quantitative detection of such treatment.

Conclusion

A novel approach using tuneable RI filler and inorganic filler with sealing provides a new way for emerald fracture filling. The process provides a better way to conceal eye-visible fractures for emeralds from different geographic origins while maintaining evaporative stability. This also fulfils certain end consumers’ wish for using non-resin type emerald fillers. However, it is noteworthy that the proposed fillers may not be able to fall into the previous classification in literature. Also, the detection of inorganic filler may require a less straightforward approach and may pose a challenge to certain qualitative and quantitative determinations. Further work has to be done for identifying better filler candidates and to fine-tune optimal reaction parameters.

Remark

The use of IF in emeralds may impose unintended weight to the stones. Further investigations are required to address the issue.

References:

- Bergman, J., Emerald Enhancements: A Consumer and Trade Guide, https://eighthdimensiongems.com/emeraldenhancements-a-consumer-and-trade-guide, accessed 1 May 2023

- Guo, H. S., Yu, X. Y., Zheng, Y. Y., Sun, Z. L. and Ng M. F. Y., 2020, Inclusion and Trace Element Characteristics of Emeralds from Swat Valley, Pakistan, Gems & Gemology, Fall 2020, Vol. 56, No. 3

- Hänni, H. A., 1993, Filled emeralds: please face reality, Jewellery News Asia, June, 76-80

- Johnson, Mary L., Elen, S., Muhlmeister, S., 1999, On the Identification of Various Emerald Filling Substances, Gems & Gemology, Summer, 82-107

- Kiefert L., Hanni, H. A., Chalain J-P., Weber W., 1999, Identification of filler substances – in emeralds by infrared and Raman spectroscopy, The Journal of Gemmology, 26, 8, 501-20